If you don’t know about it, India Foodex is occurring for the 7th year at BIEC, Bangalore. Organized by Media today group, the event occurs along with other occasions including GrainTech India, DiaryTech India, India Food Park Expo and MeatTech Asia, supplying site visitors access to a selection of equipment and devices suppliers in India.

BIEC suits its 40,000 sq. m of protected space in three functionally designed event halls, with a 5000 sq. m of open display area, flawlessly ideal for showcasing large and heavy devices. The Conference Center, The Food Court and also other assistance solutions for exhibitor as well as site visitor comfort, all within the very same facility, make BIEC an one-of-a-kind and most looked for after exhibit center, in India.

Why should you attend Foodex 2015

Include to your calendar, considering that The India Foodex in Bangalore is an internationally acclaimed event that has been producing tremendous area to food and also food, food packaging products and also products, packaging devices, food components, basic materials, tinned foods, processed foods, packaging machines as well as other similar items and also accessories. With most current of packaging methods and option, foodstuff, the occasion intends to produce a worldwide platform for the Indian food industry. The event is also understood for tossing open massive networking and support chances for potential individuals. Because 1996, MTG is supported by committed group of professionals, technocrats as well as Marketing Professionals with over a years of encounter in posting and also carrying out Events, Seminars, Workshops, Educating Programmes right from Planning to Implementation. The Group is likewise publishing really distinguished journals like Floriculture Today, Agri Company & Food Sector, Saarc Oils & Fats Today, Newspaper like AGRITECH INDIA and also Directories like APEDA Exporters Directory, Food Handling Market & Trade Directory site, Floriculture, Baby room & Landscape Sector Directory site. Find here a profile of type of exhibitors at FOODex.

BIEC – Bangalore International Exhibition Center

Where to find it:

10th Mile, Tumkur Road, Madavara Post, Dasanapura Hobli Bengaluru, Karnataka 562123 India

What screening and separation manufacturers can you find at Foodex

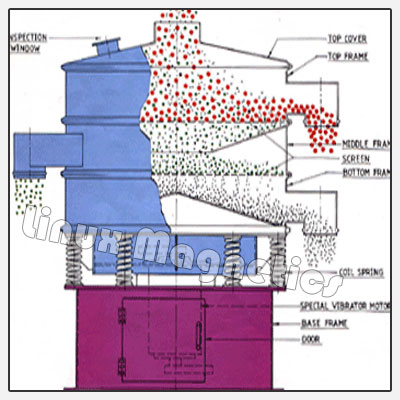

At Foodex you will find processing machinery for the food industry. Companies like Russell Finex, Galaxy Sievtek or ETA vibroscreen will be displaying their innovations in screening equipment. You will have a chance to contact with sales engineers that have good knowledge of how to solve your problems.

If you want more information about this exhibition in Bangalore, India, please visit some of the selected PR’s we found on the internet:

- At Newswire: Foodex India 2015 – Newswire provides detailed information about this event featuring Russell Finex, one of the main global vibro screening equipment suppliers.

- At 10 time India Foodex Bangalore you can find more details about location and transports to Foodex 2015.

- The Thailand website Asia Food and Beverage also covers times and contacts for Foodex in Bangalore

Once again, India Foodex 2015 is happening for the 7th year at BIEC, Bangalore. Organized by Media today group, the event happens along with various other events consisting of GrainTech India, DiaryTech India, India Food Park Exposition and MeatTech Asia, giving visitors access to a range of machines and tools providers in India. Make sure you book FOODEX on your calendar, considering that The India Foodex-Bangalore is an internationally acclaimed event that has actually been creating immense space to food as well as food, food packaging materials as well as items, packaging equipments, food ingredients, resources, tinned foods, refined foods, product packaging machineries as well as various other comparable items and also devices.

that should eradicate granules that are oversize, which retard the speed where they are going to dissolve and detract from eye-appeal of the merchandise. Display and dirt capability certainly are an issue with other kinds of sieving apparatus because the detergent is bone-dry at time of scalping. vibrating screen for chemical powders can manage the capabilities that detergent makes need, while keeping over-size material into a amount that is manageable. The sulfur dust is additionally eliminated by the application of metal handles and spout connectors (this also applies to .

that should eradicate granules that are oversize, which retard the speed where they are going to dissolve and detract from eye-appeal of the merchandise. Display and dirt capability certainly are an issue with other kinds of sieving apparatus because the detergent is bone-dry at time of scalping. vibrating screen for chemical powders can manage the capabilities that detergent makes need, while keeping over-size material into a amount that is manageable. The sulfur dust is additionally eliminated by the application of metal handles and spout connectors (this also applies to .

You must be logged in to post a comment.